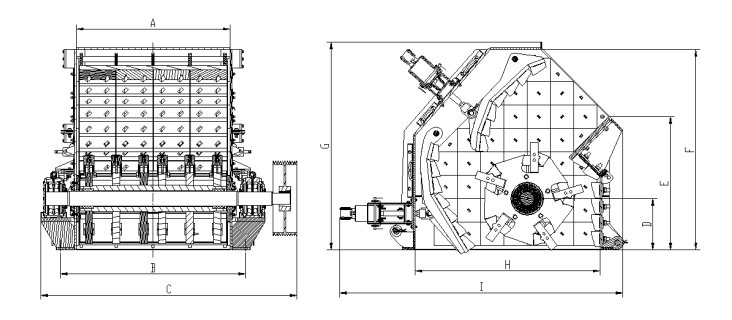

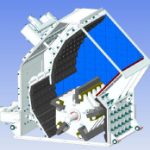

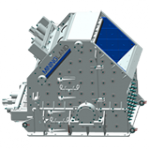

Based on its engineering experience, MININGLAND has designed a complete range of IC horizontal-axis impact crushers which are capable of meeting the demands of this market. Our intelligent design makes them very versatile. By making slight changes to their configuration, their robustness allows them to be adapted for use as primary, secondary and, in certain applications, even tertiary elements in the same crushing line. Owing to their large impact screens, they can work with reduction indexes of up to 1/20 and are also suitable for improving the production or shaping of ballast. As their shielding elements are manufactured from high-chrome or manganese steel depending on the application, they may also be used with highly abrasive products.

Based on its engineering experience, MININGLAND has designed a complete range of IC horizontal-axis impact crushers which are capable of meeting the demands of this market. Our intelligent design makes them very versatile. By making slight changes to their configuration, their robustness allows them to be adapted for use as primary, secondary and, in certain applications, even tertiary elements in the same crushing line. Owing to their large impact screens, they can work with reduction indexes of up to 1/20 and are also suitable for improving the production or shaping of ballast. As their shielding elements are manufactured from high-chrome or manganese steel depending on the application, they may also be used with highly abrasive products.

Based on its engineering experience, MININGLAND has designed a complete range of IC horizontal-axis impact crushers which are capable of meeting the demands of this market. Our intelligent design makes them very versatile. By making slight changes to their configuration, their robustness allows them to be adapted for use as primary, secondary and, in certain applications, even tertiary elements in the same crushing line. Owing to their large impact screens, they can work with reduction indexes of up to 1/20 and are also suitable for improving the production or shaping of ballast. As their shielding elements are manufactured from high-chrome or manganese steel depending on the application, they may also be used with highly abrasive products.

Based on its engineering experience, MININGLAND has designed a complete range of IC horizontal-axis impact crushers which are capable of meeting the demands of this market. Our intelligent design makes them very versatile. By making slight changes to their configuration, their robustness allows them to be adapted for use as primary, secondary and, in certain applications, even tertiary elements in the same crushing line. Owing to their large impact screens, they can work with reduction indexes of up to 1/20 and are also suitable for improving the production or shaping of ballast. As their shielding elements are manufactured from high-chrome or manganese steel depending on the application, they may also be used with highly abrasive products.